Advanced Industrial Fire Protection

Engineered Dry Chemical Suppression Systems

Experience powerful fire suppression engineered for high-risk environments with fast-acting, reliable protection.

Understanding Dry Chemical Suppression

Dry Chemical Suppression Systems are designed to combat fires in industrial settings where flammable liquids, gases, or hazardous materials are present. These systems deploy a fine powder—typically monoammonium phosphate or sodium bicarbonate—that interrupts the chemical reaction of fire, effectively extinguishing flames within seconds.

Unlike water‑based systems, dry chemical suppression is non‑conductive and leaves no residual moisture, making it ideal for protecting mechanical spaces, water‑reactive areas, industrial paint booths, trailer manufacturing operations, and other volatile environments. These systems are particularly effective in locations where rapid response is critical and where water is impractical or potentially damaging.

Key Advantages of Dry Chemical Systems

Dry Chemical systems offer robust fire protection with features tailored to industrial safety needs.

Fast-Acting Suppression

Non-Conductive Agent

Cost-Effective Installation and Maintenance

Applications of Dry Chemical Systems

Paint Booths and Mix Rooms

Fuel Storage Facilities

Mining Operations

Industrial Manufacturing

- Dip Tanks and Plating Lines: Prevent fires in chemical processing areas with systems tailored to hazardous liquid applications.

- Hazardous Material Storage: Secure storage areas for volatile substances with comprehensive fire protection.

- Power Plants and Utilities: Protect critical infrastructure with systems designed for high‑temperature and high‑voltage environments.

- Aircraft Maintenance Bays: Ensure safety in aviation facilities with non‑corrosive, fast‑acting suppression.

- Transportation Depots: Enhance fire safety in bus garages, rail yards, and logistics hubs.

- Paper and Pulp Production: Safeguard high‑risk processing zones where dust, heat, and flammable byproducts demand robust, industry‑specific fire protection systems.

- Chemical Laboratories: Safeguard research and testing environments with minimal disruption and residue.

- Defense and Military Installations: Protect sensitive operations with systems built to meet stringent safety standards.

- Automotive Assembly Lines: Ensure uninterrupted production with reliable fire suppression for machinery and paint areas.

- Warehouses and Distribution Centers: Secure large storage areas with scalable, effective fire protection.

- Garages and Workshops: Provide peace of mind in high‑risk environments with compact, effective systems.

Discover the Right Solution with Our Experts

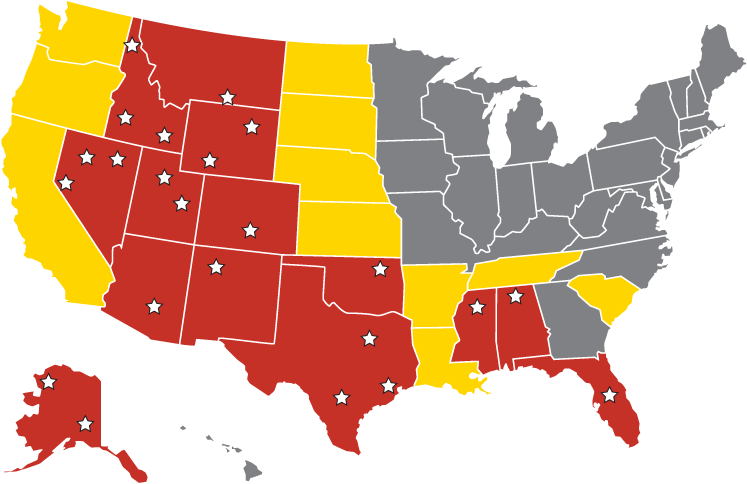

Want to explore how Dry Chemical Suppression Systems can protect your facility? Visit our contact page to speak with a State Fire expert and discover customized solutions for your needs.